Keeping bird flu at bay

- tips you should not ignore

By Jim Bigmore, managing director of hygiene specialists, Hysolv

Irrespective of whether the latest UK outbreaks have come from viruses circulating in our native birds, or from migrating birds, avian influenza, “Bird Flu” is here and cannot be ignored!

In all cases, where there is the threat of a notifiable disease, such as avian influenza, the first stop should be the DEFRA website. This source of information and advice can help farmers greatly in deciding which actions to take – firstly, to avoid the disease and, secondly, how to proceed if the worst comes to the worst and the disease is found on their farm.

In the case of avian influenza, it is a good idea to use a web search engine, such as Google, with the search “Avian Influenza Latest Situation Gov.UK”, to find out what must be done to protect the farm’s flock or flocks.

The best practice for biosecurity against influenza involves a few simple, but important, rules. These can be further simplified as:

- Don’t buy diseased birds.

- Don’t allow wild birds or other disease vectors contact with your flock directly, or indirectly through faecal matter carried on boots. Remember, humans are also disease vectors!

- Don’t allow visitors unless absolutely necessary.

- Disinfect/sanitise anything that comes onto the farm – vehicles, feed, and even water.

- When entering a poultry house, sanitise hands, disinfect/change boots, change clothes.

- Record everything and everyone that comes onto the farm.

DEFRA also tests disinfectants specifically for effectiveness against avian flu, in case it becomes a problem. The Poultry Orders test is described as “Diseases of Poultry and the Avian Influenza and Influenza of Avian Origin in Mammals” and the obligatory dilutions of disinfectants for use against avian influenza are also listed in the DEFRA list of approved disinfectants.

The DEFRA dilutions for Poultry Orders can also be found on the label of disinfectant canisters. Interestingly – or perhaps we should say worryingly – these often vary from the manufacturer’s own recommendations for the product. Sometimes by a factor of 6!

Much of this information may be well-known to most farmers and will provide enough detail for disinfecting poultry housing after cleaning. However, when dealing with vehicle disinfection and boot-dip disinfectants perhaps the following information may be new to some people:

Temperature and disinfection

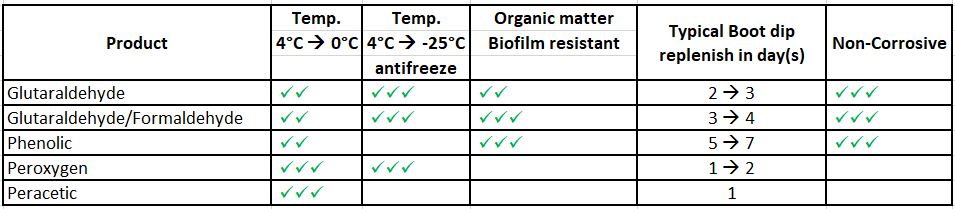

The DEFRA tests are performed at a temperature of 4°C and therefore all disinfectants tested by DEFRA will destroy the avian influenza virus in 30 minutes at that temperature.

When the temperature drops below 4°C, some disinfectants will continue to work within the same 30-minute time-period. These can be given the general description of peroxygen disinfectants, or oxidising agents, and cover disinfectants containing hydrogen peroxide, peracetic/acetic acid and potassium peroxomonosulphate.

Phenolic and glutaraldehyde-based disinfectants tend to work more slowly under 4°C, but they do work effectively. They do not stop working as implied by over-zealous salespeople of competitor peroxygen products.

Some glutaraldehyde and peroxygen products may even have antifreeze added and can be used down to -25°C!

Organic matter and disinfection

Boot dips are an essential barrier to viruses, bacteria and other micro-organisms entering the poultry house. All disinfectants work well in a boot dip when freshly diluted with clean water. However, it is inevitable that a boot dip will be subject to an increasing organic matter load as farm staff disinfect their boots entering and leaving the poultry house. Equally, well-washed vehicles can be disinfected using all types of disinfectants but, unless the vehicle is thoroughly dried first, an increased concentration of disinfectant should be used to compensate for any remaining water on the vehicle.

If vehicles are unable to be power washed in a spray gate first, then glutaraldehyde, or preferably glutaraldehyde/formaldehyde disinfectants are preferable as they are better able to cope with any remaining organic matter or biofilm, as shown in the 2011 and 2017 DEFRA/APHA disinfectant comparison tests.

Peroxygen disinfectants tend to lose efficacy due to their reaction with organic matter. Therefore, boot dips filled with these disinfectants need to be replenished very often.

Glutaraldehyde-based disinfectants are reported as not readily inhibited by organic matter, with phenolic based disinfectants even less. This results in the boot dips needing just bi-weekly, or weekly replenishments respectively (depending upon the frequency of their use).

Corrosion and disinfection

The corrosive nature of some peroxygen disinfectants is not a problem when rubber boots are used in plastic boot dips. However, when vehicles are being disinfected, it is very important to use disinfectants that are non-corrosive at recommended dilutions. Glutaraldehyde and phenolic based disinfectants are not corrosive to metal.

Summary of the key disinfectant properties

We are all very conscious of the need for scrupulous attention to hygiene in these difficult times. It really is well worth a farmer or manager’s time to thoroughly research the bio-security system and the disinfectant that is most suited to the farm’s particular situation. This effort can pay for itself many times over if just one outbreak of bird flu is avoided.